As the novel coronavirus wreaked havoc across Asia and Europe in January and early February, one University of Mississippi Medical Center professor was already worrying that a stateside outbreak would lead to a ventilator shortage in the United States. Fearing the worst, Dr. Charles Robertson, an assistant professor of anesthesiology, set out to build the “absolute cheapest, functioning ventilator from widely available parts,” he said in a UMMC announcement on Tuesday.

By the time national leaders were publicly discussing an imminent ventilator shortage in March, Robertson was already working on his device, which costs less than $100 and can be assembled in an hour using common items including garden hoses, adapters, valves, a solenoid (a coil of wire that converts electrical energy into mechanical energy) and a lamp timer.

UMMC has asked the U.S. Food and Drug Administration for emergency approval to use the devices in dire situations, but not as a replacement for more expensive ventilators, which cost thousands of dollars.

“This device is for extreme use situations during a pandemic. We would only be using these ventilators if every single hospital ventilator is in use, and we have patients that are about to die because of that,” Robertson said. He added that it could be used as a “bridge therapy” for patients to use for several hours until a regular ventilator becomes available.

Dr. John Prescott, the chief academic officer at the Association of American Medical Colleges, said in UMMC’s press statement that Robertson’s device is part of a trend of “innovation” that is happening “at academic medical centers across the nation in response to the coronavirus pandemic.”

The ‘Hub Mask’

Medical universities and colleges like UMMC in Jackson are not the only ones finding new ways to safeguard the nation’s health-care system against the contagion, though. In Hattiesburg, teams at the University of Southern Mississippi are working on several COVID-19-related initiatives.

Dr. Anna Wan, a digital fabrication specialist and the director of USM’s 3-D Printing lab, the Eagle Maker Hub, began work on a prototype after friends in Los Angeles and New York City asked her for help to deal with the mask shortage that has plagued hospitals and clinics nationwide. When Wan posted on Facebook that she was working on a solution, Hattiesburg Mayor Toby Barker sent her a message, asking for help creating masks for local health-careworkers.

Over the last weekend, she delivered a first batch of 250 respirator masks, with more on the way.

Wan’s team calls it the “Hub Mask,” both as a nod to the fact that Hattiesburg is known as “The Hub City” and because, instead of having a built-in filter, it uses a “hub” that allows users to equip it with different kinds of filters. Hospitals can use the hub to connect an existing n99 filter, the one used in a hospitals nationwide.

“I feel like this could potentially disrupt the industry,” Wan said in USM’s announcement on Tuesday. “The fabric masks health-care workers are currently using still serve a purpose, but what we’ve come up with is phenomenal in terms of the suction to the face.”

Wan, who is a mathematician, worked with professionals at Hattiesburg Clinic and Forrest General Hospital to create the mask, ensuring not only that it featured the appropriate suction, but that it would remain breathable. Her team included Dr. Joe Campbell, Forrest General’s chief anesthesiologist; Dr. Brittany Coberly, Forrest General’s director of respiratory therapy; Dr. Steven Stogner, Forrest General’s ICU director; and Dr. John Fitzpatrick, a Hattiesburg Clinic nephrologist.

Wan hopes the masks’ use can someday extend beyond just pandemic emergencies, though.

“I have a staff that have volunteered to test these and have worn them around to try and find flaws and they truly love them,” she said. “It is my hope that these masks can go down the route of getting further approval on these and hoping one day a mask like this can be what we use as a n95. They are that comfortable. It’s not often that different health-care providers and researchers come together to make something like this happen, but this speaks to how successful that can be when you get key players together.”

Each mask costs about $2 to make. In its announcement, USM said Wan and Dr. Monica Tisack Kathmann, the director of USM’s polymer institute, are seeking funding to scale up production.

‘We’re All In This Together’

Teams, working with local radiologist Dr. Will King, are also using 3D printing technology at the University of Mississippi in Oxford in the school’s J.D. Williams Library. Staff from UM’s Haley Barbour Center for Manufacturing Excellence and the IDEAlab are printing reusable face shield headbands for use at the town’s Baptist Memorial Hospital-North Mississippi. The headbands’ clear plastic visors will give health-care workers an extra layer of protection, and also make it safer and easier to reuse the n95 masks that are in short supply.

Scott Kilpatrick, CME’s director of academic programs, praised UM staff and faculty in an announcement on Thursday.

“Here on campus, we are fortunate to have resources in places like the CME and the IDEAlab that can provide support in some way,” he said. “Even individual UM faculty and staff are using their own personal 3D printers to contribute as best they can.”

King’s team made the face shields, in part, by purchasing clear plastic presentation covers. The covers can be thrown away after each use, and a new one can be attached to the headband.

CME began producing the face shields on April 2, and plans to print 400 by the end of the month. Some of the headbands are also going to New York, where hospitals have faced extreme shortages and health-care professionals have even resorted to wearing garbage bags in place of regular protective equipment, UM’s library manager, Christina Streeter, said in Thursday’s announcement.

Universities are helping in ways other than just innovating, though.

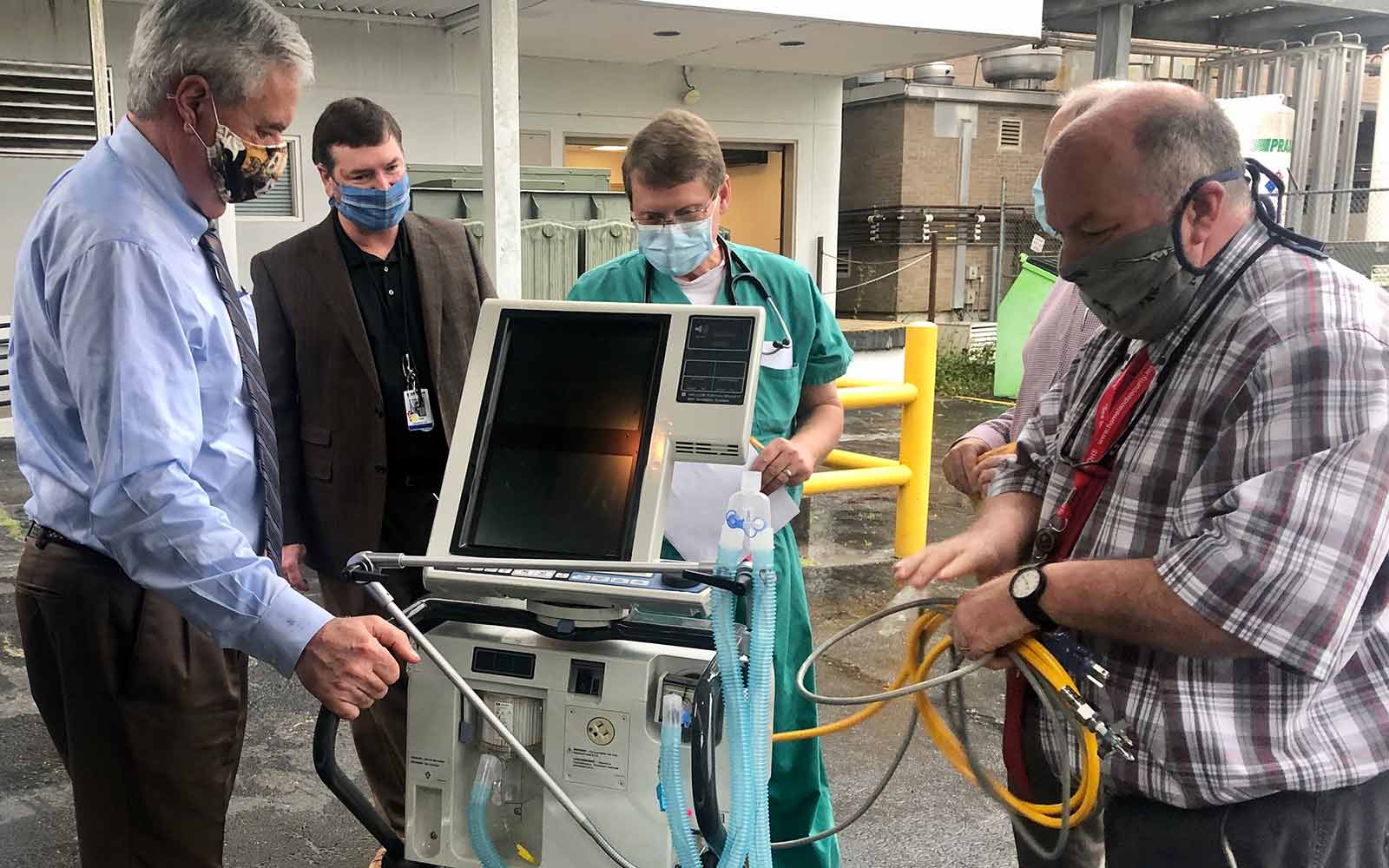

Mississippi State University’s College of Veterinary Medicine loaned two ventilators to the town’s OCH Regional Medical Center earlier this month.

“When it comes to COVID-19, we’re all in this together and happy to share resources and clinician assistance in fighting this terrible virus,” said Dr. Kent Hoblet, the dean at MSU’s College of Veterinary Medicine. “We’re acutely aware of the need and are working with local, state and national leaders to help ensure the best possible outcome for this unprecedented event.”

More information on coronavirus prevention measures is available at the University of Mississippi Medical center’s website at umc.edu/coronavirus and at cdc.gov/coronavirus.

The Mississippi Free Press has an interactive map showing diagnosed coronavirus cases across the state and one showing the number of ICU beds in counties across the state.